Japanische Messer Shop - SCHARFE MESSER aus Japan

Seit vielen Jahrhunderten lebt in Japan die traditionelle Handwerkskunst der Messer- und Schwertschmiede. Nicht ohne Grund ist diese Tradition bis heute erhalten geblieben und findet weiterhin neue Anhänger.

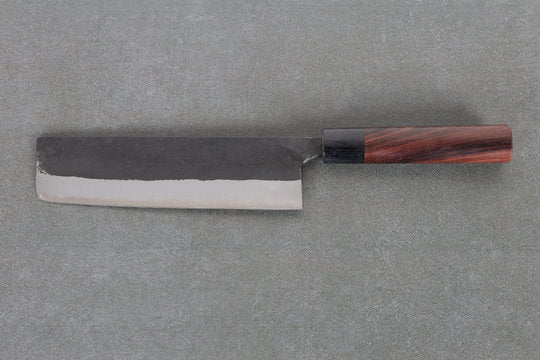

Die wichtigste Eigenschaft ist, dass ein Küchenmesser scharf ist. Aus diesem Grund wurde es Hergestellt. Wir importieren original japanische Messer die man sonst schwer findet und bringen die schärfsten Klingen nach Europa!

In diesem Shop findest Du handgeschmiedete japanische Messer, die darauf warten, zu Dir nach Hause zu kommen.

Entdecke traditionelle japanische Messer

Beliebte Blogartikel

Langlebig Scharf-Messer aus Japan

Interessierst Du dich

für japanische Messer? Dann wirst Du begeistert sein, wenn Du erfährst, wie

scharf Messer sein können. Japanische Küchenmesser sind konstruiert, die

schärfste Schneideleistung zu liefern und „Scharf“ bedeutet nicht nur scharf,

sondern auch eine zuverlässige scharfe Leistung über einen langen Zeitraum.

Wir bieten eine breite Palette an traditionellen japanischen Messern DIREKT aus

Japan. Unsere hochqualitativen Messer wurden sorgfältig getestet und bieten das

beste Preis-Leistungs-Verhältnis. Zusammen mit unseren Pflegehinweisen und

Schleifanleitungen kannst Du dein neues japanisches Kochmesser leicht pflegen

und scharf halten!